Wet sanding and polishing are essential steps to achieving a smooth, high-gloss paint surface. While it may seem intimidating to use sandpaper on new paintwork, it is a necessary process to eliminate the orange peel texture that remains after painting. Wet sanding involves using increasingly fine sandpaper, from 1000 to 3000 grit, to level the paint's surface and remove imperfections. After sanding, buffing is done to restore shine and add depth to the paintwork. This can be achieved by hand or with an electric buffer, but caution must be exercised to avoid burning the paint. Hand polishing is effective for light scratches and swirl marks, while deeper scratches may require machine buffing or paint correction. The choice between hand and machine polishing depends on personal preference, skill level, and desired results.

| Characteristics | Values |

|---|---|

| Purpose | To achieve an ultra-deep, smooth-as-glass, high-gloss paint surface |

| Tools | Sandpaper, soft colour sanding block, bucket, soapy water, electric buffer, foam pad, hand polish, applicator pad, wax, car ceramic coating, backing pads, buffing pad, soft clothes, polishing compound |

| Techniques | Wet sanding, colour sanding, buffing, block sanding, machine polishing, hand polishing |

| Considerations | Ensure the paint is cured, work in sections, use even strokes, gradually increase sandpaper grit, use a "test spot", use firm but not too hard pressure, be careful near corners and edges, use overlapping strokes, follow manufacturer's directions |

What You'll Learn

Wet sanding

Before beginning the wet sanding process, ensure that the paint is cured enough to work with. It is recommended to wait several days or even weeks to allow the clear coat to fully cure. Once the paint is ready, fill a bucket with water and a small amount of automotive soap or dish soap. Do not use a soap that also contains wax or polish. The lubricant is necessary to prevent the sandpaper from burning the paint. Cut the sandpaper sheets in half lengthwise so that they can be more easily wrapped around a sanding block. Soak the sandpaper in the soapy water for about five minutes, then wrap it around a soft sanding block.

When sanding, use even, smooth strokes without applying too much pressure. Use different stroke directions to achieve a "cross-hatching" effect. Start with a lower grit sandpaper, such as 1000 or 1500, to remove the majority of the imperfections. Rinse the area as needed, and move up to a higher grit sandpaper, such as 2000 or 3000, as you work. Remember to keep the sandpaper and the surface wet throughout the process, adding more soapy water as necessary. Dry the surface occasionally to check your progress. You'll know you're done with this step when the surface looks polished but still has a slight haze.

After wet sanding, you can move on to the buffing process to bring out the shine in your vehicle's paint. Remove any excess soap, dust, and sandpaper grit by washing down your vehicle with fresh water and drying it with a lint-free cloth. Choose an appropriate buffing pad and attach it securely to your buffer. Apply polish to the pad and switch it on, being careful not to put too much compound on the pad to avoid burning the paint. Start with a low RPM, and work in small sections to avoid overheating any one area.

Troubleshooting Print Image Issues in MS Paint

You may want to see also

Using the right sandpaper grit

Sandpaper grit is sized by a gauge number, with lower numbers signifying larger, coarser grits. For example, #24- or #40-grit sandpaper is a very coarse, rough sandpaper, while #1,000-grit paper is extremely fine with very small abrasive particles. The grit number of sandpaper is almost always clearly printed on the back of the sandpaper itself. Grit numbers range from #24 all the way up to #4,000, although most people will never use grits at the top or bottom of this scale.

In automotive bodywork and other painted metal applications, it’s crucial to select the proper sandpaper grit sizes because the varying degrees of textures impact the final results. When removing paint or rust, you need a coarse grit, but the resulting rough surfaces will need finer grits for smoothing. While the grit range varies depending on the sanding application, in most instances, you move from coarser grits to finer ones, scraping off old coatings and polishing new ones.

For flattening and polishing new paint by hand, you will need to start with a coarse grit sandpaper to strip off any caked-on paint. Then, you will need to smooth out those areas with a higher-grit, less intense sandpaper. For this process, you will need sandpaper in the range of 24 to 40 grit, with 30-grit sandpaper being suitable for high-intensity sanding. Once you've stripped the paint, you can move on to smoothing out those areas with a higher-grit sandpaper. The 320 to 400 grit range is excellent for this final stage before applying the primer.

After this, you can move on to the final sanding before applying paint, which requires a 600 to 800 grit range to sand imperfections and polish the surface for paint application. Finally, use 1,500 to 4,000 ultra-fine grit for wet sanding imperfections and polishing the surface after a clear coat. It's important to gradually increase the grade of your sandpaper to eliminate coarser scratches from the paint, levelling the paint's surface with finer and finer scratches that can eventually be hidden with polish.

Equip Paint Finishes: Rocket League Guide

You may want to see also

Buffing

Preparation

Before beginning the buffing process, it is crucial to ensure that your painted surface is ready for buffing. Firstly, determine if your paint job has cured sufficiently. If you are working on a vehicle, leaving it in direct sunlight for at least 24 hours can help accelerate the curing process.

Choosing the Right Tools

The choice between hand buffing and machine buffing depends on your preference and the desired outcome. Hand buffing is a traditional method that can yield satisfactory results, especially for removing light swirl marks and surface imperfections. However, it is labour-intensive and may not be as effective for deeper scratches. Machine buffing, on the other hand, achieves better results due to the heat generated, making it more efficient in removing scratches and swirl marks.

If you opt for hand buffing, choose a suitable compound and polish. Meguiar's Ultimate Compound and Meguiar's Ultimate Polish are highly regarded for their effectiveness in removing scratches, swirl marks, and restoring shine. Ensure you have a clean buffing pad, foam applicator pads, and lint-free or microfiber cloths.

The Buffing Process

Start by applying a small amount of your chosen compound to the buffing pad. Work the compound slowly and methodically into the paint, using a flat hand to apply firm but not excessive pressure. Focus on working out any imperfections and swirl marks left behind by the swirl remover. Remember to tape off any panel gaps to protect edges and prevent compound from getting into unwanted areas.

Finishing Touches

Once you have completed buffing the entire surface, it is time to apply a wax or ceramic coating. This step will seal in the shine and protect your paint job. Choose a pure polish without fillers to achieve the best results. Check the product's chemical base to ensure it is suitable for your needs.

Calculating Room Area for Painting Projects

You may want to see also

Polishing compounds

Abrasive compounds are designed to remove surface imperfections and scratches from the paintwork. These compounds contain abrasive particles such as aluminium oxide or silicone carbide, which effectively smoothen out scratches and swirl marks caused by natural wear and tear. However, abrasives can also leave behind their own marks, so it is important to follow up with a polishing compound.

Non-abrasive compounds are the perfect choice for enhancing the shine of your paint without removing any material. These compounds use polishing agents such as oils and waxes to bring out the depth and gloss in your paintwork. Non-abrasive compounds are ideal for maintaining the paint's finish and protecting it from the elements.

All-in-one compounds offer the best of both worlds by combining the effects of abrasive and non-abrasive compounds. They are designed to remove imperfections while also enhancing the shine. This type of compound is a great choice if you want to streamline your polishing process and achieve both correction and protection in one step.

Rubbing compounds are heavier-duty abrasives used to tackle more severe issues such as heavy oxidation, water spots, and stains. These compounds are more aggressive and are often used with coarser pads to effectively remove defects that regular polishing compounds cannot.

When choosing a polishing compound, it is important to consider the condition of your paintwork and the level of correction needed. For light swirl marks and surface imperfections, an abrasive compound followed by a non-abrasive or all-in-one compound will likely be sufficient. For deeper scratches and more severe defects, a rubbing compound followed by a protective non-abrasive compound may be required.

Additionally, it is worth noting that hand polishing is a viable option for those who may be hesitant to use machine buffers. While it requires more effort, hand polishing can effectively remove light swirl marks and imperfections. However, for deeper scratches and more extensive correction, machine buffing or paint correction services are recommended.

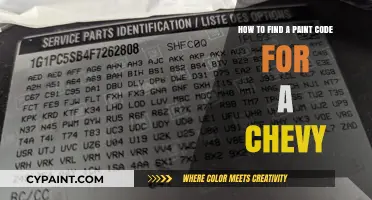

Finding Your Ford Crown Victoria's Paint Code

You may want to see also

Sealing with wax

Waxing by hand can be challenging as the human hand tends to apply pressure irregularly, which can result in pressure points that may damage the paint. These pressure points are caused by your fingertips and can mar the paint depending on its softness or hardness.

To wax by hand, use a flat hand and not the tips of your fingers. Apply firm pressure, but not too hard, so the applicator pad does not roll out of your hand. Always use a pure polish without fillers, checking the bottle's chemical base to ensure it does not contain them.

Machine waxing is generally considered safer for the paint than hand waxing, as it applies wax evenly in a flat, uniform application that is not too thick. Machine waxing also leaves less residue to wipe away. However, hand waxing can be a good option for those who lack the confidence to use a machine polisher.

It is important to note that the paint should be polished and free of wax or sealants before applying wax. Additionally, a cleaner/wax can be used to clean, polish, and protect the paint in one step, but this is only recommended for paint in neglected condition, not excellent condition.

Reviving Glow-in-the-Dark Paint: Simple Solutions for Dry Paint

You may want to see also

Frequently asked questions

Wet sanding is the process of using sandpaper to remove texture or "orange peel" from the surface of the paint. It is done by hand and can be used to remove foreign contaminants, runs, overspray, and paint oxidation.

It is recommended to start with a lower grit sandpaper, such as 1000 or 1500, and work your way up to a higher grit, such as 3000. The higher the grit, the finer the scratches, which can eventually be hidden with polish.

Make sure your paint is cured before starting the wet sanding process. If you have access to a baking oven, you can use that to cure the paint. Otherwise, leaving your vehicle in direct sunlight for at least 24 hours should be sufficient.

After wet sanding, you will need to buff the surface to bring out the shine. This can be done by hand or with an electric buffer. If using an electric buffer, set it to a low RPM (around 1500-1800) to avoid burning the paint.

Apply a small amount of your chosen hand polish to an applicator pad and work it slowly into the paint, using a flat hand and firm pressure. Continue until the entire vehicle is complete, then apply a wax or ceramic coating to seal in the shine.