Painting a forklift without taking it apart is a great way to make it look brand new and slow down the wear and tear process. Before painting, it is important to clean the forklift thoroughly, removing all grease, oil, and dirt. It is also crucial to disconnect the battery terminals and wrap them in tape to prevent grounding. To avoid damaging the hydraulics, the forks should be unfastened and the fork holders lowered onto pallets. Once the necessary prep work is done, you can select your paint, keeping in mind OSHA regulations regarding paint type and the need to ventilate the area and wear personal protective equipment.

| Characteristics | Values |

|---|---|

| Cleaning | Remove grease and dirt from the forklift, especially the mast, which is often covered in grease. Use thinners, steam cleaners, or chemical thinners for this step. |

| Battery Terminals | Disconnect and wrap the battery terminals in tape to avoid grounding. |

| Forks and Fork Holders | Remove the forks and lower the fork holders onto pallets to avoid damaging the hydraulics. |

| Painting Preparation | Use painter's tape to cover areas that should not be painted, such as decals, plates, controls, and nameplates. |

| Paint Type | Choose good-quality, non-flammable paint with non-combustible solvents and a high flash point (100 degrees F or higher). Consider paint toxicity and ensure the area is well-ventilated. |

| Personal Protective Equipment | Wear safety masks, paint goggles, gloves, and an airline respirator if painting in a confined space. |

| Spray Painting | Only use battery-powered forklifts in spray rooms. Gas, diesel, or propane-powered forklifts are not allowed due to spark risks. |

| Drying | Do not move the forklift until the paint is completely dry. |

| Professional Service | Consider hiring a professional service provider for a neater and safer job. |

What You'll Learn

Clean the forklift thoroughly, removing grease, oil, and dirt

To prepare your forklift for painting, it is important to clean it thoroughly, removing any grease, oil, and dirt. This step is crucial as forklifts are notorious for being covered in grease, especially on the mast. Start by uncoupling and taping the battery terminals to prevent them from grounding. Next, remove the forks and lower the fork holders onto pallets to protect the hydraulics.

Now, focus on degreasing the forklift. Use a steam cleaner or chemical thinner to remove grease, especially from the inner parts of the lift equipment and the inside of the runners of the mast, as these areas tend to be dusty and gritty. If you opt for a chemical thinner, scrape away the grease. Don't forget to strip off any existing paint from the inside runners where the fork holders move.

After degreasing, ensure you thoroughly clean the forklift to remove any remaining oil and dirt. A steam cleaner can be useful for this step as well. Pay extra attention to the mast, ensuring it is free from dust, grease, and any other debris. It is important to clean the forklift as thoroughly as possible, as the paint will adhere better to a clean surface, and this deep clean may not be repeated for another five to ten years.

Once the forklift is clean and dry, you can proceed with the next steps of preparing the surface for painting, such as taping off areas to protect them from paint and ensuring adequate ventilation and personal protection as mandated by OSHA.

Crafting Realistic Action Figures: Painting 5 O'Clock Shadow

You may want to see also

Disconnect and tape battery terminals

Painting a forklift can be a messy and time-consuming job, but it's a great way to make your forklift look brand new. Before you start painting, it's important to take the necessary safety precautions, especially if you're working with spray paint or other toxic materials.

One crucial step in preparing a forklift for painting is disconnecting and taping the battery terminals. Here's a step-by-step guide on how to do this:

- Park the forklift in a well-ventilated area away from any business operations, as per OSHA guidelines.

- Put on personal protective equipment, such as gloves and a safety mask.

- Locate the battery terminals.

- Disconnect the battery terminals by uncoupling the battery cable. It is recommended to shut off the charger before unplugging, to avoid any potential issues.

- Wrap the disconnected battery terminals with tape to prevent them from grounding out or creating a spark.

- If there are any signs of corrosion or dirt on the terminals, clean them using a solution of baking soda and water, or a brass brush.

- Once the terminals are clean and dry, you can proceed with the painting process, ensuring that you follow all relevant safety guidelines.

By disconnecting and taping the battery terminals, you reduce the risk of electrical issues during the painting process. It is important to note that you should not move or operate the forklift while the paint is drying.

Repositioning Text Boxes in Paint 3D: A Simple Guide

You may want to see also

Tape over decals, plates, and controls

Painting a forklift is a great way to breathe new life into an older machine. However, it is important to be aware of relevant rules from the US Occupational Safety and Health Administration (OSHA). One of the key mandates is that all forklift labels and nameplates must be readable at all times. Painting over these would make the forklift unsafe for operation. Therefore, it is crucial to tape over any decals, plates, and controls before painting.

When preparing to paint a forklift, it is essential to thoroughly clean the machine and remove any grease, oil, or dirt from its surfaces. This includes scraping away grease from the inside of the runners of the mast, which tends to be particularly greasy and grimy. To avoid damaging the hydraulics, it is recommended to unfasten the forks and lower the fork holders onto pallets. Additionally, ensure that the battery terminals are disconnected and wrapped in tape to prevent them from grounding.

After completing the necessary cleaning and preparation, it is time to focus on protecting specific areas from the paint. Painter's tape should be applied to cover the inside where the fork guide runs. It is also essential to tape off other areas, such as decals, plates, and controls. By doing so, you can ensure that the paint only adheres to the intended surfaces and that important information remains visible.

Using tape to cover decals, plates, and controls is a crucial step in the painting process. It ensures compliance with OSHA regulations and helps maintain the forklift's safety and operability. By carefully applying tape to these areas, you can create crisp, clean lines and avoid accidentally painting over vital information or controls. This attention to detail will result in a professional-looking finish.

Once the painting is complete and the paint is dry, carefully remove the tape from the taped-off areas. This will reveal the decals, plates, and controls, ensuring they remain clear and easily readable. By following these steps and paying attention to the details, you can successfully paint your forklift without taking it apart, giving it a fresh and refreshed appearance.

Creative Ways to Link Paint and Plate with a Word

You may want to see also

Choose a non-flammable paint with a high flash point

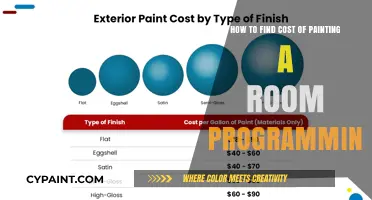

When choosing paint for your forklift, it is important to select a paint brand with non-flammable solvents. The paint you choose should include a high flashpoint of 100 degrees Fahrenheit or more. This is because the Occupational Safety and Health Administration (OSHA) has set guidelines that only noncombustible agents or solvents with a high flash point can be used on forklifts.

A flash point is the temperature at which a substance will ignite and burn. Flammable paints have a low flash point, meaning they can burn at standard working temperatures. Conversely, a combustible material has a high flash point and will only burn at higher-than-standard working temperatures. In general, oil-based paints are flammable, whereas water-based paints are non-flammable. However, there are exceptions, such as dried acrylic paint, which is flammable. Therefore, it is important to check the label on the paint you buy to confirm.

OSHA Standard 1910.94 mandates spray-finishers to isolate their operations in spray rooms apart from business operations. This standard must align with the 1910.178 standard when spray painting occurs, as only electric industrial trucks can be used in areas where combustible particles are normally present in the atmosphere. Gasoline, diesel, and liquid petroleum gas-powered forklifts must not drive through paint or spray rooms as they do not have the same spark-limiting safeguards as electrical fittings.

Before painting, it is important to take the necessary precautions based on the toxicity of the paint. If you are painting inside a garage or dock, you must ventilate the area and wear personal protective equipment, such as a safety mask, paint goggles, gloves, and a respirator.

Patching Aluminum Siding Holes: Prep for Painting

You may want to see also

Ventilate the area and wear protective equipment

Ventilation and protective equipment are key considerations when painting a forklift. OSHA rules and safety guidelines must be followed to ensure a safe painting process. Firstly, it is crucial to ventilate the area where the painting will take place. This helps to prevent the buildup of toxic fumes and ensures a safe breathing environment. Open doors and windows, and if possible, set up fans to promote airflow.

Secondly, wearing personal protective equipment (PPE) is essential. The type of PPE required depends on the toxicity and flammability of the paint being used. At a minimum, a safety mask, paint goggles, and gloves should be worn to protect your respiratory system, eyes, and skin from paint exposure. If the painting is done in a confined space, an airline respirator is mandatory.

Additionally, it is important to be mindful of the concentration of solvent vapors. Keep the concentration below 10% of the lower explosive limit to mitigate the risk of an explosion or fire. If highly volatile paints are being used, take extra precautions to safeguard the painter's face, eyes, head, and hands. Coveralls and protective suits can provide additional protection from paint splatters and fumes.

It is also worth noting that certain paints are regulated for use on forklifts. Only noncombustible agents or solvents with a high flash point (defined as 100 degrees F or higher) are permitted. These regulations are in place to prevent fire hazards and ensure the safety of the painter and those in the surrounding area.

By following these ventilation and protective equipment guidelines, you can ensure a safe and compliant painting process for your forklift.

Finding Pittsburgh Paints' PPG Numbers: A Quick Guide

You may want to see also

Frequently asked questions

First, park the forklift in an area separate from any business operations. Then, clean the forklift thoroughly, removing all grease, oil, and dirt. Uncouple the battery terminal and wrap them in tape so they don't ground out. Remove the forks and lower the fork holders onto pallets to avoid damaging the hydraulics. Next, strip off the paint on the inside runners and cover any areas you don't want to paint, such as decals, plates, and controls, with painter's tape.

It is recommended to use a good quality paint with non-flammable solvents and a high flash point of 100 degrees F or higher. You should also consider the toxicity of the paint and ensure the area is well-ventilated.

If painting inside a confined space, wear an airline respirator to protect yourself from solvent vapors. If using highly volatile paint, protect your face, eyes, head, and hands. Additionally, ensure the forklift is not running and remains stationary until the paint is completely dry.

Depending on the type of paint used, it could take a couple of hours to a couple of days for the paint to dry.