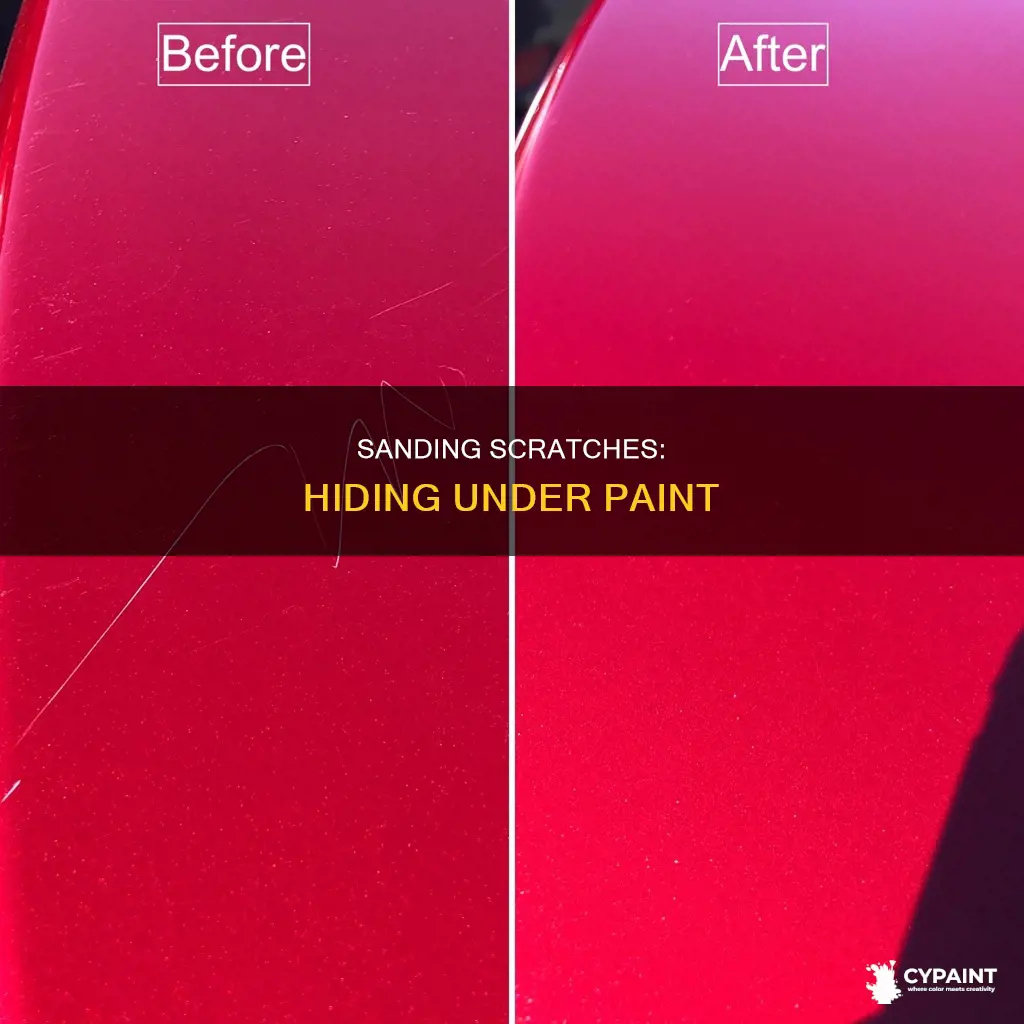

Sanding marks or scratches are a paint defect that appears under the finish coat. They are mainly caused by incorrect grit usage, poor prep work, and a lack of paint filling power. To prevent sanding marks, it is important to follow the correct sanding technique, using the right grit in a staggered way. For example, starting with 400-grit sandpaper for solid colours and 600-grit for metallic surfaces. If scratches are already present, they can be filled with a sealer or primer before painting. However, if the scratches are deep, the only option may be to repair the affected area from scratch, reapplying the intermediate coat and finish paint.

Characteristics and Values

| Characteristics | Values |

|---|---|

| Cause of sanding scratches | Incorrect grit choice, poor prep work, incorrect sanding technique, or lack of paint filling power and levelling |

| Solutions | Seal the surface before painting, sand with finer paper, use a sealer, apply a new finish coat, repair the affected area, use a sanding guide, sand with the grain, use a machine instead of sanding by hand, use a high-build polyurethane primer, apply more coats of paint |

What You'll Learn

Choose the correct grit size for the sanding paper

Sandpaper grit is what makes it abrasive. Manufacturers grade sandpaper based on the size of the grit, and the grade you need depends on the job. The grit number of sandpaper is almost always clearly printed on the back of the sandpaper itself. Grit numbers range from #24 all the way up to #1,000, although most people will never use the extreme values.

The main cause of the appearance of sanding marks is related to an incorrect choice of grit used for sanding the putty or filler. If you choose a coarser grit than what is recommended, it will cause a mark that is too deep to be levelled by the paint layer.

Coarse grits, such as #24, #30, #36, #40, #50, and #60, remove a lot of material quickly, like sanding paint off wood or sanding out deep gouges. Coarse grades are available in 9- x 11-inch sheets, belts for drum and belt sanders, and disks for disk sanders.

Medium grits, such as #80, are often the first grade chosen when preparing wood for finishing. They can be used to hand sand or with a belt or orbital sander. Medium grits are also good for removing rust and corrosion from metal. Medium grits will leave a coarse surface texture, so they will need to be followed up with fine grit sandpaper afterward, depending on the finish you desire.

Fine grits, such as #120, are typically used for second or third sandings. Sometimes, fine-grit sandpaper is used to roughen glossy paint in preparation for applying another coat. Fine grits are available on 9- x 11-inch paper or cardboard sheets, or on precut backings for machines like detail or random orbital sanders.

Ultra-fine grits, such as #800 and #1,000, are used to achieve another level of smoothness on all types of materials. With wood, ultra-fine grits are usually reserved for smoothing painted surfaces between coats. Many finer grits are used for wet sanding, which creates a fine, gritty slurry that complements the sandpaper's efforts at smoothing.

When choosing sandpaper, it’s important to select the right grade for the job. A paper that’s too coarse will leave the surface scratched and damaged, while one that’s too fine won’t do the job.

Finding Corel Painter's Serial Number: A Guide

You may want to see also

Use a sanding guide for better control

When it comes to sanding surfaces in preparation for painting, one of the main challenges is avoiding sanding marks or scratches that show through the paint. These marks are caused by using a coarser grit than recommended, which creates grooves that are too deep to be levelled by the paint layer.

To avoid this issue, it is advisable to use a sanding guide for better control of the surface being sanded. A sanding guide helps you maintain a consistent technique and pressure, reducing the likelihood of creating deep grooves that will show under the paint.

When using a sanding guide, it is important to follow the proper sanding technique. This includes using different sandpaper grits in a staggered manner, progressing from coarser to finer grits. For example, you might start with a coarse grit like 180 to remove existing material or imperfections, then move to 240, 320, and 400 grit, changing directions by 90 degrees between each grit.

It is also crucial to smoothen the sanded surfaces after sanding. This step enhances paint coverage and levelling, resulting in better anchoring and performance of the final paint finish. Additionally, make sure to follow the drying times established in the technical data sheet for the intermediate coats to ensure optimal results.

By using a sanding guide and following the proper sanding techniques, you can significantly reduce the appearance of sanding scratches and achieve a smoother, more professional paint finish.

Eliminating Orange Peel: Single-Stage Paint Perfection

You may want to see also

Smoothen the surface to enhance paint coverage and levelling

When preparing a surface for painting, it is important to smoothen the sanded areas to enhance paint coverage and levelling. This process improves the anchoring and performance of the final paint finish.

Sanding marks or grooves are a set of scratches that have not been covered or filled in with the paint coat. They are mainly caused by using a coarser grit than recommended, creating marks that are too deep to be levelled by the paint layer. To avoid this, it is crucial to follow the product's technical data sheet, which specifies the recommended grit size. Additionally, using a sanding guide can help control the sanding process and prevent the appearance of sanding marks.

For finish coats, it is advisable to use smaller orbits, while the eccentric movement should exceed 5 mm when sanding the filler. Following a proper sanding technique is essential, using different sandpaper grits in a staggered manner. Starting with a finer grit and gradually increasing it can help remove deep scratches effectively.

In some cases, such as when using Benjamin Moore Advance paint, light sanding between coats may be recommended. However, for enamels, it is generally advised to avoid sanding between coats, as two top coats are typically sufficient without the need for additional sanding.

If scratches are visible under the paint, it may be necessary to resurface and prepare the area again, ensuring proper smoothing and levelling before applying the finish paint. This will help prevent the appearance of sandpaper marks and create a uniform and smooth finish.

Michael Godfrey's Paintings: Pricing and Value Guide

You may want to see also

Seal the surface to fill in scratches before painting

If you are sealing a surface to fill in scratches before painting, it is important to follow a few key steps to ensure a smooth and uniform finish. Firstly, choose the appropriate grit size for sanding. A finer grit paper, such as 400 to 600-grit, will help to smooth out scratches and create a finer finish. Starting with a coarser grit, such as 180-grit, may be too aggressive and can leave deeper scratches that will show through the paint. It is also important to use a sanding guide and the correct sanding technique, such as sanding in a crisscross pattern, to avoid the appearance of sanding marks.

Once you have sanded the surface with the appropriate grit, the next step is to apply a primer. A primer will help to create a uniform surface and enhance the adhesion of the paint. It is important to choose the right type of primer for your project, such as a high-build polyurethane primer or a two-part epoxy primer. Follow the instructions on the primer's technical data sheet for the best results. After applying the primer, give it a light sand to smooth out any imperfections.

If necessary, you can apply a sealer after the primer to help fill in any remaining scratches. Sealers are useful for encapsulating any existing imperfections and creating a uniform base for the paint to adhere to. However, some sources suggest that a sealer may not be necessary if the surface is thoroughly primed. Consult with experts or refer to product instructions to determine if a sealer is required for your specific project.

After sealing, you may need to sand the surface again with a finer grit, such as 600-grit, to ensure that the scratches are adequately filled and smoothed out. This step will depend on the specific project and the severity of the scratches. Finally, you can proceed to apply the paint according to the manufacturer's instructions, ensuring that you follow the proper painting techniques for the best results.

By following these steps and taking the time to prepare the surface properly, you can effectively fill in scratches and create a smooth and uniform finish before painting.

Join Mendes' Painted Love Academy: Here's How

You may want to see also

Apply a new finish coat to conceal sanding marks

If you're dealing with sanding marks or scratches that are visible under the paint, one solution is to apply a new finish coat to conceal them. This approach can be effective, but it's important to understand the underlying causes of the issue to ensure the best results.

Sanding marks are primarily caused by using a coarser grit than recommended, resulting in scratches that are too deep to be levelled by the paint layer. It is crucial to follow the instructions provided in the product's technical data sheet to select the appropriate grit size. Additionally, using a sanding guide can help improve control and prevent the appearance of sanding marks.

Before applying a new finish coat, it is essential to prepare the surface properly. This includes smoothing the sanded areas to enhance paint coverage and levelling. Proper smoothing will also improve the anchoring and performance of the final paint finish. Make sure to follow the drying times specified in the technical data sheet for the intermediate coats.

If the sanding marks are visible in the primer coat, you may need to strip the paint and start again with proper prep work. This could involve using a finer grit to sand the area and then applying a new finish coat. It is worth noting that simply applying more coats of paint may not be enough to conceal the sanding marks, especially if the scratches are deep.

In some cases, it may be necessary to repair the affected area from scratch. This involves preparing the intermediate coat again and then applying the finish paint. This method ensures that the sanding marks are completely removed and provides a smooth surface for the new finish coat.

By understanding the causes of sanding marks and following the appropriate preparation techniques, you can effectively apply a new finish coat to conceal the sanding marks and achieve a smooth and uniform finish.

Repairing Streaks on a Painted Side Table

You may want to see also

Frequently asked questions

To prevent sanding scratches from showing under the paint, you must ensure that you are using the correct grit size for the job. If you use a coarser grit than recommended, it will cause marks that are too deep to be levelled by the paint layer. You should also smoothen the sanded surfaces to enhance paint coverage and levelling.

The grit size to be used will be specified in the product’s technical data sheet. However, as a general rule, 320-400 grit is about as coarse as you want to go unless you are priming or putting down a sealer. For finish coats, use smaller orbits.

If the scratches are in the top coat, they will likely polish out. If they are below the top coat, you may need to strip the paint and start again.